Selecting an optimal mold base is of critical importance in injection molding; it forms the basis for producing high-quality parts. Here we explore several key recommendations when it comes to picking mold bases.

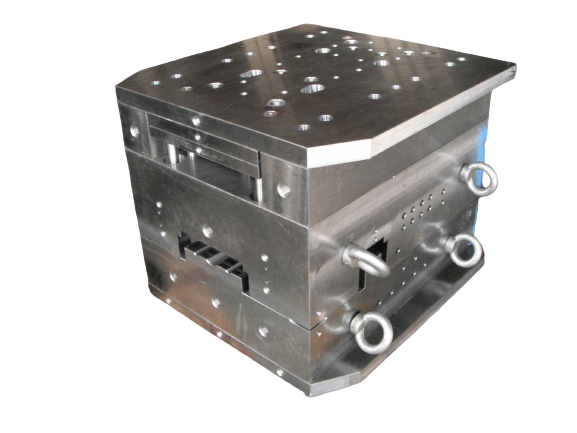

When ordering the standard mold base for the second board mold, several dimensions that must be determined are the length and width of the mold; The thickness of the front and rear templates (the thickness of A and B plates); The height of the mold foot.

For example, what does it mean to see the ordered HC1630A50B60C80 on the drawing?

HC – Code of the mold base manufacturer;

1630- The width * length of the mold is 160mm * 300mm

A50- The thickness of the cavity plate is 50mm

B60- The thickness of the core plate is 60mm

C80- Support block thickness is 80mm

So how are these key data dimensions derived in actual mold design? More estimation is based on design experience. Below are a few design experience suggestions for reference only.

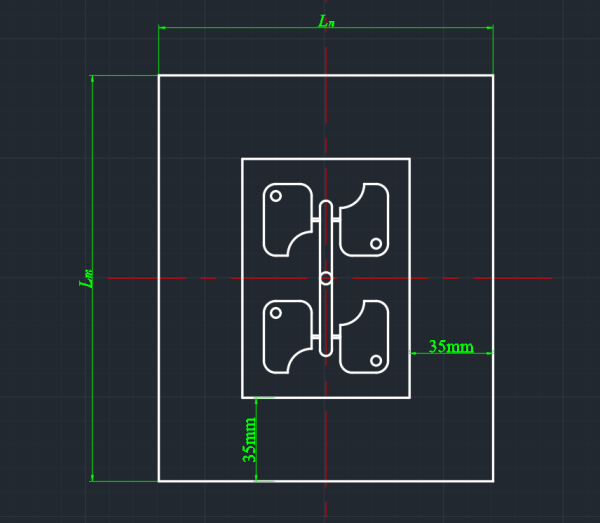

- The distance between the edge of the mold core and the edge of the template should not be less than 35mm, usually taken as 50mm or more.

- The distance between the bottom surface of the fixed mold core and the bottom surface of the fixed template shall not be less than 20mm, and it is often taken as more than 30mm. The thickness of the fixed mold core embedded into the fixed template shall not exceed 2/3 of the thickness of the fixed template.

- The distance between the bottom surface of the moving mold core and the bottom surface of the moving template should not be less than 30mm, usually taken as over 35mm. The thickness of the moving mold core embedded in the moving template shall not exceed 2/3 of the thickness of the fixed template.

- Ejection distance=total height of the product+minimum safety margin of (10-20) mm.

- The height of the C-board is equal to the ejection distance+the thickness of the upper and lower ejection boards (usually 40-45mm)+ the thickness of the stop pins (usually 5mm).

Based on the above suggestions, it is easy to calculate the length Lm and width Ln of the mold base, the thickness A of the cavity plate, the thickness B of the core plate, and the thickness C of the support block. Note that the calculated dimensions must be rounded to whole numbers, and then based on these dimensions, the corresponding specifications of the mold base can be ordered.