The choice of plastic molds is based on the life of mold, the properties of plastic, the function of internal parts, and mold cost. However, materials are usually selected to have the following properties.

Excellent machinability

The vast majority of plastic molds are subject to various cutting or assembly operations, so excellent machinability is necessary for mold machining. For example, it is possible to extend the life of machining tools, improve cutting performance and reduce the roughness of a machined surface.

Good surface hardness and wear resistance

The hardness of most plastic molds is below 50-60 HRC. Some molds that require heat treatment will have a more than adequate surface hardness to ensure that they can withstand the pressure and friction of plastic flow during the injection work. The good hardness and wear resistance will guarantee the accuracy and stability of the products produced, in order to achieve the desired service life of mold.

Good polishing performance

Highly demanding plastic products often require very small roughness values on cavity surfaces. For example, the roughness of cavity surface must be less than Ra 0.1 to 0.25, and for optical surfaces Ra < 0.01 nm, so cavity surface must be polished or ground to achieve the required roughness. In addition to this, the material selected must not contain defects such as impurity or porosity.

Stable heat treatment

If the shape of plastic product is more complex, it may be more difficult to process it after heat treatment, so choose a material with good heat treatment stability as far as possible. After heat treatment, the mold deformation is small and the temperature-induced dimensional changes are small so that the required dimensions and surface roughness of mold can be guaranteed.

Higher corrosion resistance

Some plastic materials and additives can produce corrosive gases, which can cause the surface of cavity to dissolve and ultimately affect the quality of plastic products. It is best to use corrosion-resistant steel or to have cavity surface chromium plated to improve the corrosion resistance of the surface.

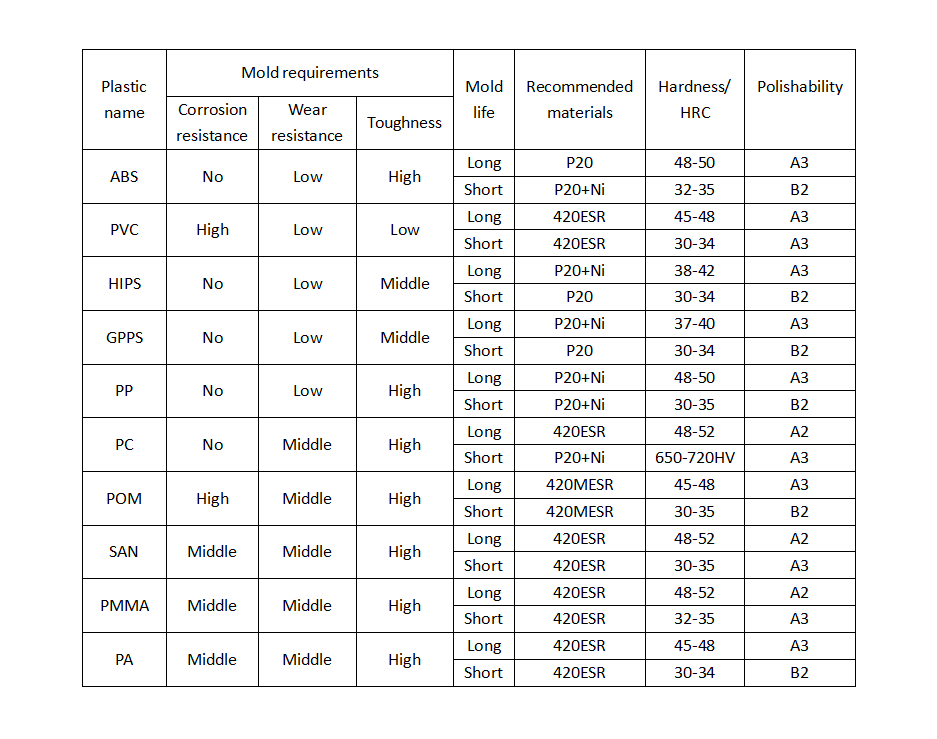

The most common mold materials will be selected according to plastic characteristics, the specific requirements are shown in the table below

With the development of the plastics industry, the increasing complexity and precision of plastic products, and thus the requirements for mold materials are also more demanding. At the same time, if there is relative movement on two surfaces, the same material should be avoided and in special cases, one side can be nitrided or chromium plated to give the two sides a different surface structure.